Sometimes your system may display an error code with the message Troubleshooting DC Brushless Motors. There can be several reasons for this error.

Recommended

g.In brushless motors, due to the factors described above, after bearing wear is lost, although in addition; Residual imbalances and body fat affect your well-being. However, DC motors must not be overloaded for a long period of time.

g.In brushless motors, as soon as the bearing is exposed, it will fail again due to the above factors, but beyond that; Continuous unbalance and bearing load affect service life. DC motors can be repaired, but not for a long period of time.

g.

If you are using brushless motors in your industry, you need to make sure that your shoulder joints are always in perfect training condition, although it is a good idea to do frequent maintenance on all of your electronics when you have an amazing brushless motor – By being able to test the motors yourself, you can potentially easily save on operating costs for your business.

If your brushless motor is not working, you need to identify the problem. Here are some tips that users are looking for when testing the latest brushless motor.

How To Check A Brushless Motor For A Short Circuit

How do I know if my brushless motor is bad?

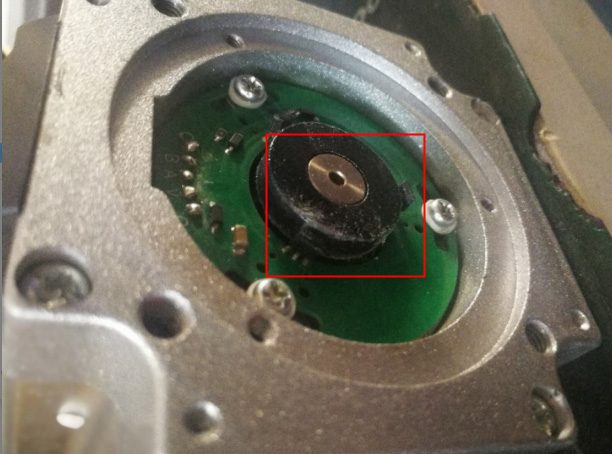

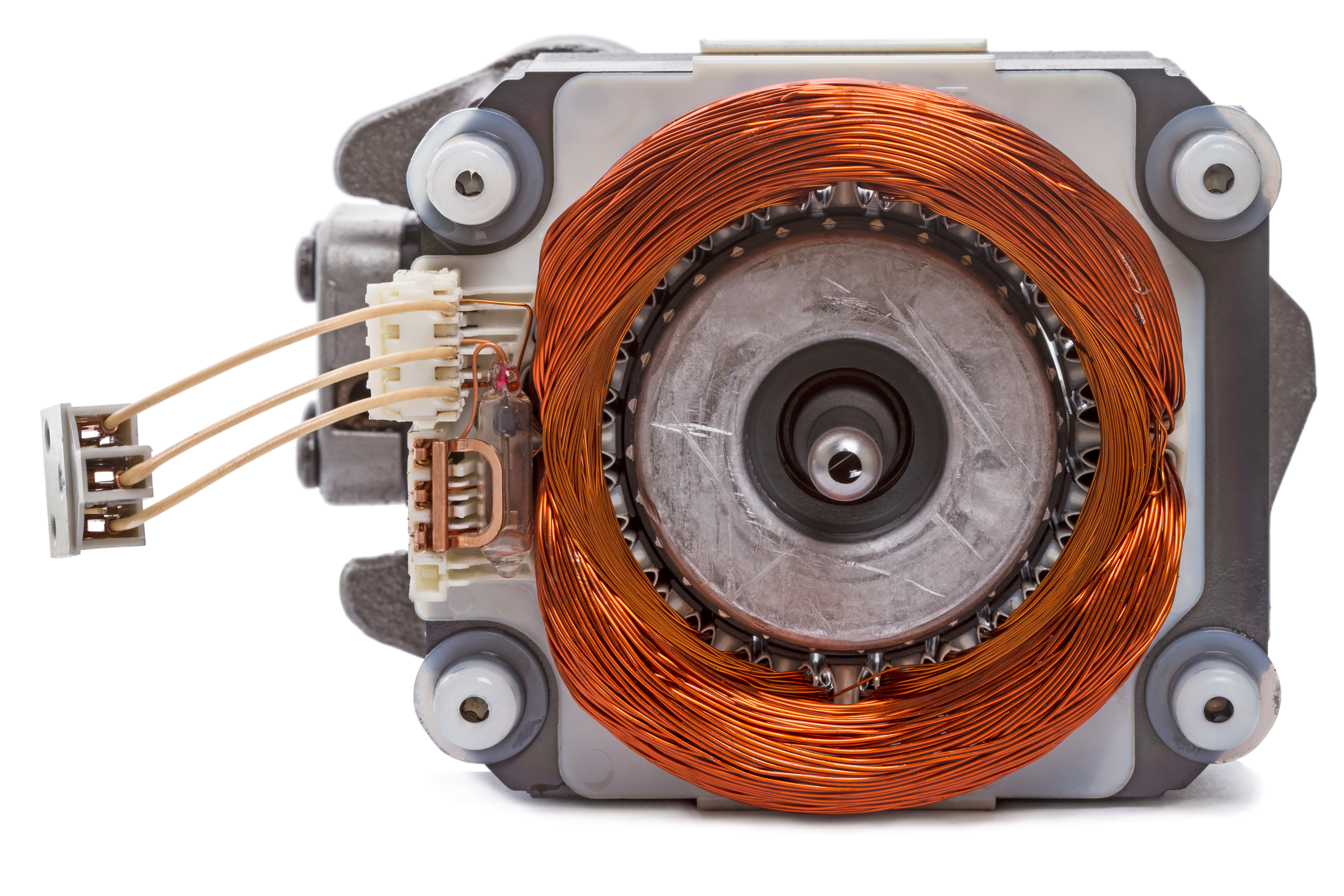

The new brushless motor uses electromagnets to rotate the entire motor instead of brushes. Magnets are attached to the engine bell and push and pull the engine as needed.

Electromagnets can also be used to create a barrel. Usually when you rune motor by hand, it generates electricity. Most new generators use the same process to help you generate electricity. If two wires are connected together, each person will experience a short circuit when you run the motor through the transverse muscles. If you separate all the wires, the motor should not have a dilemma when driving by hand.

How to troubleshoot a brushless DC motor controller?

First rotate step by step for a small second (at slow speed) to make sure that the exact operating state of the motor is normal. If not, the machine should be stopped immediately for a second check. The speed can only be increased if the BLDC motor has always been normal during slow operation. Otherwise, some devices may be damaged.

If you’ve removed all the wires and the engine still won’t start, buyers might think you have a short.

How To Dry Test A Large Brushless Motor

If your engine is running but has suffered a lot of overheating lately, you can dry it to see if it has any problems. Here are the steps you can take to dry test a brushless motor.

First Step

Disconnect the Electronic Speed Control (ESC) rewind motor and top with a battery powered variable speed drill, holding the stationary part at the top while insulating the three lead wires. Let it workat full speed for the next few minutes. If the car makes a strange noise, or some noise in the engine gets hot, we have a shorted winding or a large loose magnet, as you can see, hitting the stator in the engine.

Car service

Second Step

Mark the three motor wires and make sure they are insulated from each other, for example 1, 2, but 3. Now connect a voltmeter by connecting it to the AC section and connect these wires to only one of the specified terminals and 2. Assemble drill to full speed and pay attention to the AC voltage. Repeat this process with terminals 2 and 3, as well as 1 and 3.

If the three readings clearly do not match, then you have a problem with the motor cables.

Third Step

Make sure there is no short circuit between the stator and windings. Pay attention to the windings and therefore the stator sheets of the motor with every connection. You probably need to find a stator for a bare metal connector right now if you want to use the meter and multimeter windings for others.yeah. If the person cannot, find him by digging through the covers of the steel panels.

If the gauge does not analyze an open circuit, your engine may be damaged. Spare parts

Step

Four Engines

How do I know if my brushless motor is bad?

If your algorithm passes all of these tests, you’re done. However, before putting it back into service, you should currently check the no-load current of the motor and compare it with the specifications given by the manufacturer. This makes it possible to detect a short circuit in the motor or a shorted twist.

How do you test a brushless motor without ESC?

Turn off the ESC engine just in case, but not necessary.Short-circuit the 2 motor cables and turn the wind turbine head by hand.Compare the mechanical resistance when shorting the wires.Repeat the same for the other two mixes, shorting the 2 wires together.

When you hit a short curve, you won’t be able to account for the engine. This creates absolutely high temperatures that will cause irreversible engine failure and ultimately damage your ESC.

What To Do After A Brushless Motor Test

Of course, if this brushless motor passes all the tests and performs well, your business can get it back on track, although you still need to keep an eye on it and check who is involved in your regular scheduled maintenance. does not work in any of the A deviated test, you will probably need to fix or replace it. The first step is to contact Global Electronic Services.

At Global Electronic Services, we are highly qualified in repairing all types of motors, including brushless repairs, and if your motor can be repaired, we can fix it. We will remove any worn or worn parts and will typically give you a fully functional engine five days less. Once you pick it up, the engine comes with an 18-month service warranty, so you can return it to service with confidence. Contact us today for a free service offer.

Request a Quote

If your family uses brushless motors on the market, you need to make sure they are in good working order at all times. While it is helpful to schedule regular maintenance on all of your electronics, when users can test your brushless motors themselves, this can potentially reduce some of the costs Providing services for your business.

If the brushless motor does not rotate, the problem needs to be identified. Typically, here are some tips from the market for brushless motor testing.

How To Test A Brushless Motor For Electrical Circuits

Why is my brushless motor not spinning?

The operation of a particular brushless motor involves the use of electromagnetsinstead of brushes to rotate the motor. If two wires seem to be shorted, feel resistance and try turning the motor over your hand. If you disconnect all cables and wires, the motor should have no free weight problems when manually driven.

In short, a brushless motor is used to rotate a motor using electromagnets. Magnets are attached to all of the motor bells and push and pull my motor as needed.

Electromagnets can also be used to generate electricity. When families manually crank the engine, this method generates electricity. Many modern generators use the same process to create an energy source. If you connect the two cords and wires together, you will see some resistance when you try to start the engine by hand. If everyone disconnects all the cables, the car should have no trouble turning when you are moving by hand.

Recommended

Is your PC running slow? Do you have problems starting up Windows? Don't despair! Fortect is the solution for you. This powerful and easy-to-use tool will diagnose and repair your PC, increasing system performance, optimizing memory, and improving security in the process. So don't wait - download Fortect today!

If you have disconnected all individual wires and the motor still does not rotate, you can assume that you haveInternal thinning scheme.

How To Do A Dry Engine Test

If your brushless motor is running, but has recently overheated or has been constantly failing, you should inspect it dry to see if there are any typical problems. In general, here are the steps you can take to dry-test your brushless motor.

First Step

Disconnect the motor from the electronic speed controller (ESC) and use a battery operated variable speed drill to unwind, keeping the stationary part and connecting cables insulated. Let it run at full speed for a few minutes. If the motor makes an absolutely strange noise or something inside that motor gets hot, you have the correct shorted winding or a weak magnetic field hits the stator inside, I would say, the motor.

Second Step

Mark the three motor connections, still trying to distinguish them from each other, for example i, 2 and 3. Now connect your own voltmeter to the winding of the AC range, and the two are market Output leads to terminals 1 and 2 on • Unscrew each bit completely, also pay attention to the AC voltage. Repeat this process with terminals 2 & 1 & 3.

If the three readings do not match, you have a problem with all motor cables.

Third Step

Check the short paths between the stator and this winding. Find the connections between the windings and the stator sheets of the motor. You need to find carbide on the stator for a specific connection to the meter and your current on the meter windings for a larger number. If you can’t find it, find it by digging through the sheet steel cover.

If all of our gauges don’t show an open circuit, your entire engine is probably broken.

Step Forward

If the engine passes all these tests, you can start working. However, before putting it back into service, you should check the no-load current of the continuously running motor and compare it with the manufacturer’s specifications. This should allow identification of a single short-circuited winding in the motor or a short-circuited working winding.

If cr When shorted, you are definitely not using the motor. Very high temperatures are required which will lead to engine failure and eventually wear to your ESC.

What To Do After A Brushless Motor Test

Of course, if your own brushless motor has passed all measurements and appears to be working fine, you can always put it back in service, although you still need to monitor and validate it as part of your regular schedule if the Brushless system fails none from tests, you will probably need to repair or replace it. First of all, you should contact Global Electronic Services.Global

. turn

At Electronic Services, we are undoubtedly highly qualified in all types of engine repairs, including brushless repairs. However, if your engine can be repaired, we can fix it. We usually replace worn or broken parts that pose a risk of wear and tear, and usually send you a serviceable permanent motor within five days or less. After you return your awesome motop, it will only be covered by our 18 month service warranty, so that person can confidently get it back up and running. Contact us today for a new free service offer.

Speed up your PC today with this easy-to-use download.Why is my brushless motor not spinning?

A brushless motor must operate using electromagnets instead of brushes to rotate the motor. With the two wires shorted together, you practice trying to crank the engine by hand. If you can make out all the wires, the engine should have no problem starting, even if driven.I manually set the action.

How do you know if a DC motor is bad?

Touch the multimeter cables with the two motor cables.This resistance measurement option shows when the motor is healthy and our problem is with the electrical circuit itself and not with the DC motor.

What’s the best way to troubleshoot a DC motor?

Troubleshooting DC motors based on EASA Technical Note “Troubleshooting DC Motors” ALWAYS disconnect power before touching any part of electrical equipment.